Super-Dry Desiccant Air Dryers, Air Compressor Filter Dryers, Mini Dryer Solutions & More

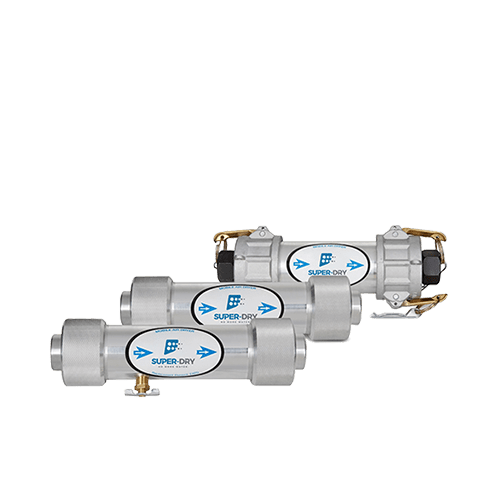

Single-tower compressor desiccant air dryer designed for point-of-use applications...

Inline desiccant air dryers perfect for air tools and paint guns...

Mini separators, filters and dryers designed for air preparation...

Water separators have been designed for the efficient removal of bulk liquid...

Compressed air filters effectively remove up to 99% of contaminants present in the compressed air...

Automatic timer drains are designed to provide a solution for the automatic draining of filters, separators, receivers, drip legs...

Desiccant air dryers work by removing moisture from the air. This is done using a process called adsorption when molecules of water are drawn to the surface of a solid material. The most common type of desiccant used in air dryers is activated alumina, a very porous material that can adsorb large amounts of moisture.

There are two types of air desiccant dryers – single-tower and twin-tower (regenerative and non-regenerative). Regenerative desiccant air dryer systems work by heating the air that the desiccant material has adsorbed. This causes the water molecules to be released so they can be condensed and removed from the system. Non-regenerative air dryers extract moisture-laden air and discharge it outdoors.

Desiccant air dryers are an improved type of dehumidifier. Because they use desiccant materials to adsorb moisture from the air they are much more effective than traditional dehumidifiers. This is the main reason why desiccant dryers for air compressors are so popular, amongst many other benefits such as:

One of the main benefits of air desiccant dryers is improving air quality. By removing moisture from the air, desiccant air dryers can also help remove mold spores, bacteria, and viruses. This can improve your respiratory health and overall well-being, especially if you suffer from allergies or asthma.

Another benefit of compressor desiccant air dryers is that they can help prolong the lifespan of your electronics. Moisture is one of the biggest enemies of electronics, as it can cause corrosion and rust. Using a desiccant air dryer can help keep your electronics in good working condition for longer.

Desiccant dryers for air compressors also have the benefit of being energy-efficient. However, because they remove more moisture from the air than traditional dehumidifiers, they can help lower your energy costs. Some models can save you up to 50% on your energy bill!

Desiccant dryers have many different applications across many various industries. They are commonly used in industries where moisture in the air could cause problems such as food spoilage, drug degradation, or corrosion of metal components.

The food and beverage industry strictly controls the air’s moisture. Unfortunately, too much moisture can spoil food, create mold, and promote bacterial growth. In addition, desiccant air dryers are often used in food processing plants and storage facilities to keep the air dry and free of contaminants.

The pharmaceutical industry also has strict standards for humidity levels in the air. Moisture can degrade drugs, so removing it from the equation is as important as possible. In addition, desiccant dryers are commonly used in drug manufacturing and storage facilities to keep moisture levels low and ensure the quality of the drugs.

When it comes to aircraft, every component must be perfect before it can be used. That’s why the aerospace industry uses desiccant dryer to remove any moisture from the environment during the manufacturing process. By doing so, they can avoid potential problems arising from corrosion or rust.

Like aircraft components, electronic components must also be perfect before they can be used. Moisture can cause electronics to short circuit, which is why air compressor desiccant dryers are commonly used during the manufacturing process to remove any moisture from the environment and ensure that the finished product is working correctly.

The military often has to operate in harsh environments where conventional drying methods are not practical or possible. That’s why the military sometimes uses desiccant air dryers to remove moisture so equipment can be properly stored without fear of rust or corrosion.

Download our latest product catalog for product specifications and ordering information.

Copyright © 2025 | Super-Dry Systems Inc.