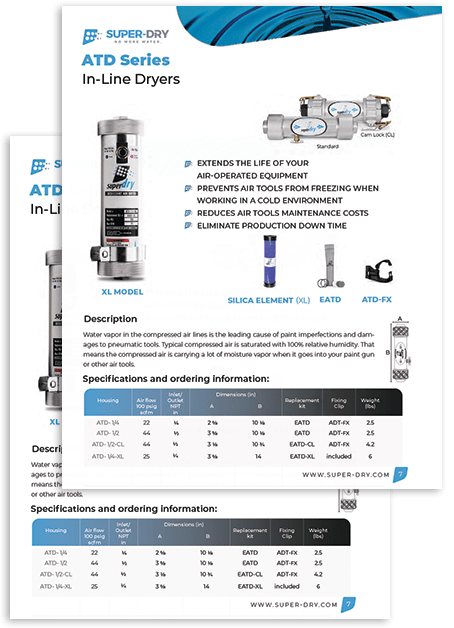

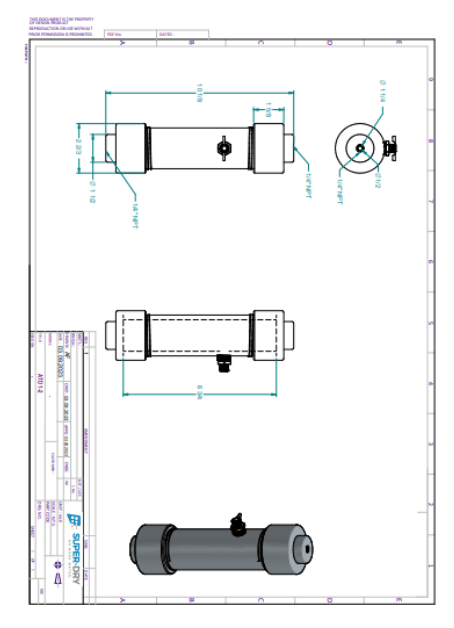

An inline dryer is used to remove water vapor from compressed air. The compressed air goes into the inlet of the inline dryer and then passes through a chamber that contains a desiccant material. The desiccant absorbs the water vapor from the compressed air, and the now-dry air exits through the outlet.

An inline dryer for air compressors is a great way to extend your equipment’s life and save energy costs. Here are three benefits of using an inline dryer.

One of the benefits of using an inline dryer for air compressors is that it reduces wear and tear. When moisture in the air condenses, it can cause rust and corrosion to build up on your equipment. This can lead to costly repairs down the road. Using an inline dryer, you can remove the moisture from the air before it has a chance to condense, which will prolong the life of your equipment.

Another benefit of using an inline dryer for air compressors is saving energy. When moisture condenses on your equipment, it can cause it to run less efficiently. This means your compressor will have to work harder to maintain the same output level, which uses more energy and drives up your energy costs. Using an inline dryer, you can keep your equipment running at peak efficiency, saving you money on your energy bill.

In addition to extending the life of your equipment and saving money on energy costs, using an inline dryer for air compressors also improves air quality. Moisture in the air can contain contaminants like dust, pollen, and mold spores, which can cause respiratory problems for people with allergies or asthma. Removing the moisture from the air can improve indoor air quality and create a healthier environment for your employees or customers.

Compressed air is a versatile and powerful resource that is used in a wide variety of industries. It can be used for manufacturing, automotive work, construction, and more. Many businesses use an inline dryer for air compressors to ensure that the compressed air is free of moisture, contaminants, and particulates. Some of these include:

While most air compressors come with a built-in dryer, there are some situations where an inline dryer is a better option. So if you’re in the market for an inline dryer for your air compressor, here are a few tips to keep in mind.

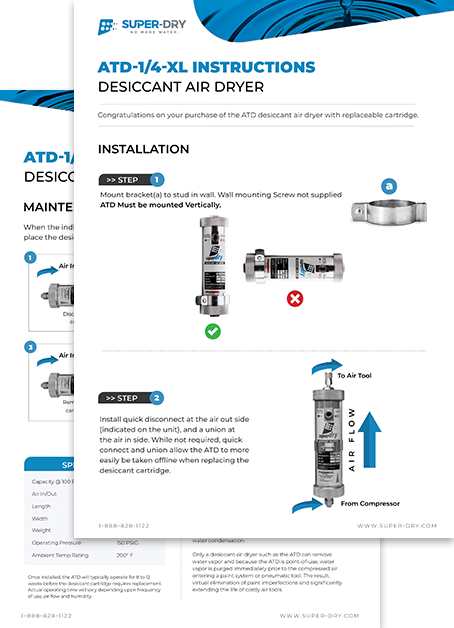

The first step is to know the specific requirements of your air compressor. Inline dryers are available in a wide range of sizes and capacities, so choosing one that is properly sized for your needs is essential. Be sure to determine your compressor’s maximum flow rate and operating pressure before making a purchase.

There are two main types of air compressors – oil-free and oil-lubricated. Oil-free compressors don’t require lubrication, so they don’t require a pre-filter. So if you have an oil-lubricated compressor, you’ll need to choose an inline dryer compatible pre-filter.

The dew point is the temperature at which water vapor condenses out of the air. When compressed air is cooled, the water vapor in the air can condense and turn into liquid water. This can cause rust and corrosion inside the air compressor and damage any tools or equipment that uses the compressed air. To prevent this from happening, you’ll need to choose an inline dryer that can lower the compressed air’s dew point to a safe level for your application.

Inline dryers are available with either NPT or BSPP connections. NPT (National Pipe Thread) connections are widely used in North America, while BSPP (British Standard Parallel Pipe) connections are more common in Europe and Asia. Be sure to choose an inline dryer with the right type of connection for your needs.

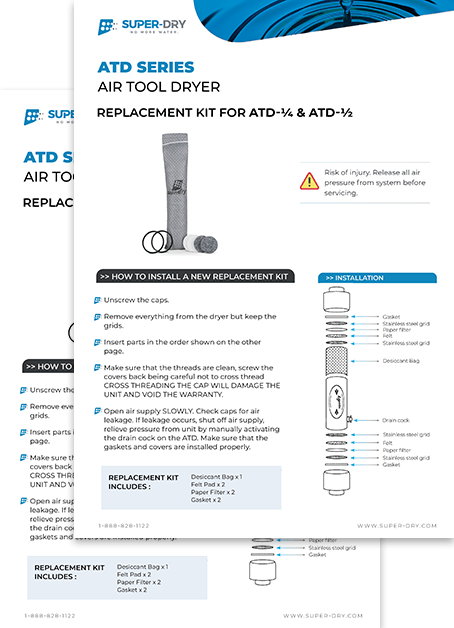

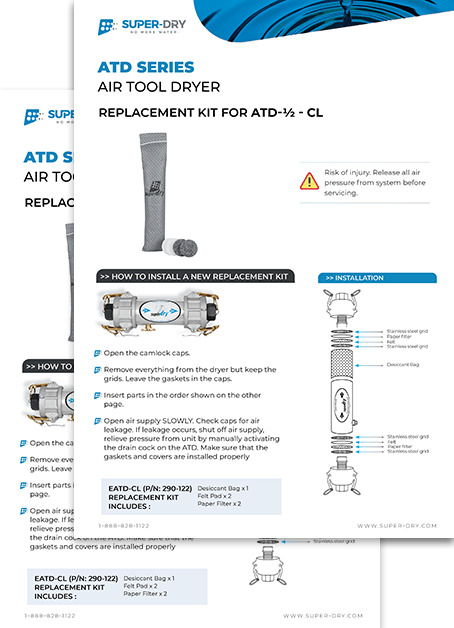

Finally, compare the maintenance requirements of different inline dryers before making a purchase. Some units require frequent filter changes, while others have self-cleaning features that minimize maintenance requirements. For example, choose an inline dryer that will be easy to keep up with, so you can keep your air compressor running smoothly.